Creating premium playing cards is an intricate process that requires expertise in design, material selection, printing, and finishing. The final product—a deck of high-quality custom playing cards—is the result of meticulous craftsmanship at every step, from the initial design phase to the packaging. Whether they’re for promotional purposes, special events, or personal use, producing top-tier playing cards requires attention to detail and a combination of advanced technologies and traditional craftsmanship. The manufacturing process of premium playing cards begins with design and ends with custom packaging that complements the card’s aesthetics and functionality. Let’s walk through each of these stages to understand the meticulous steps involved in crafting a premium deck of playing cards.

Design Phase

Collaboration with Designers

The first stage in producing premium playing cards is the design phase. This is where the vision for the cards comes to life, and it often involves collaboration between the client and experienced graphic designers. Whether a company is commissioning custom cards for promotional purposes or an individual is creating a one-of-a-kind gift, the design process begins with a conversation about the style, theme, and purpose of the cards.

Designers work closely with clients to understand their needs, preferences, and the message they want to convey. This stage involves selecting colors, themes, and elements to create a unique, cohesive design that resonates with the intended audience. Designers also consider the structure of the deck, such as the layout of the court cards, number cards, and the back design. A strong design foundation sets the tone for the entire production process, ensuring that the final product meets the client’s vision.

Choosing Software and Tools

Once the design concept is solidified, designers turn to specialized software tools to create the detailed artwork that will adorn the cards. Adobe Illustrator and Photoshop are industry standards for creating vector graphics and detailed artwork, allowing for precise designs that can be scaled to the correct size. These tools also allow designers to manipulate colors, add text, and integrate logos or illustrations.

Advanced software enables designers to create intricate details and refine the layout before it is sent to production. This is crucial for ensuring that the final print has sharp edges and high-quality graphics, which are particularly important for premium playing cards that aim to stand out in both aesthetics and functionality.

Material Selection

Choosing the Right Material

The next step in manufacturing premium playing cards is selecting the right material. The material used for the cards greatly impacts their durability, texture, and overall feel. While there are various options, the most common materials for high-quality playing cards are paper, PVC, and plastic. Each material has its benefits, depending on the intended use and budget.

Paper: Traditional playing cards are made from high-quality paper stock, often with a layer of coating for added durability. Paper cards provide a classic, smooth feel and are often used for standard playing card decks, such as those used in casinos or card games.

PVC: PVC playing cards are highly durable and water-resistant. They’re less likely to wear out, bend, or become damaged over time. PVC cards are ideal for high-traffic environments, such as casinos or professional card players.

Plastic: Plastic playing cards offer the best of both worlds—durability and flexibility. These cards tend to feel more premium than paper options and are more resistant to bending and tearing. Premium plastic cards are often used for special occasions, high-end casinos, or promotional giveaways.

Impact of Material on Quality

The material choice has a direct impact on the cards’ tactile experience. PVC and plastic cards feel more substantial and have a luxurious texture, while paper cards offer a more classic and flexible feel. The thickness of the material also plays a role in how cards handle during play. Premium playing cards are often thicker than standard cards, which adds to their durability and longevity. The material choice also affects the printing process, as different materials absorb ink at different rates, influencing the final print’s vibrancy and sharpness.

Printing Process

Advanced Printing Technologies

The printing process is where the design comes to life. High-quality printing technologies are used to ensure that the final product is sharp, vibrant, and durable. The most common method for printing premium playing cards is CMYK full-color printing. This method uses four color channels—cyan, magenta, yellow, and black—to produce a wide range of colors and gradients that make designs appear bright and dynamic.

In addition to standard full-color printing, premium playing cards often undergo specialized printing techniques, such as UV coating and embossing. UV coating helps protect the cards from wear and tear by adding a layer of glossy finish that enhances the colors and provides extra durability. Embossing is another technique used to create texture on the cards’ surface, adding a luxurious, tactile quality to premium decks.

Ensuring High-Quality Print

The printing quality of playing cards relies heavily on the printers used. High-end printing machines, such as those made by Heidelberg or Xerox, offer superior precision and color accuracy. These machines ensure that each card is printed with the same level of quality and consistency, reducing the chances of defects or misprints. The quality of the paper and ink used also plays a critical role in achieving a sharp, vibrant print, making it essential to use top-grade materials to achieve the best results.

Cutting, Finishing, and Packaging

Precision Cutting

Once the cards are printed, they are carefully cut to their final size and shape. Precision cutting is essential for achieving uniform, sharp edges. This process involves a machine that cuts the cards into perfect rectangular shapes, ensuring that every card in the deck has the same size and consistency. Quality control checks are performed at this stage to ensure that each card is free of defects and meets the brand’s standards.

Finishing Options

To enhance the tactile experience of the playing cards, finishing is applied. Common finishes include glossy, matte, and linen textures. Glossy finishes give cards a shiny and smooth texture, while matte finishes offer a more subdued and non-reflective look. Linen finishes are often used for premium playing cards, offering a textured surface that feels luxurious and makes handling easier. The finish also affects the card’s durability and how it feels in the hands, which is important for cards that will be used frequently.

Packaging Customization

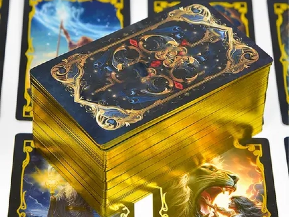

The final step in the production process is packaging. Customized packaging is often just as important as the design of the cards themselves. Premium playing cards are typically sold in custom-printed boxes that match the design of the cards. These boxes may be made from sturdy cardboard, paper, or plastic and often include features like magnetic closures, embossed logos, or foil accents. Packaging not only protects the cards during transportation but also serves as a marketing tool, as a well-designed box enhances the overall appeal of the product.

Conclusion

The process of creating premium playing cards is an intricate and precise craft that spans design, material selection, printing, cutting, finishing, and packaging. Each phase is executed with attention to detail to meet the highest standards of quality. From collaborating with designers to select the ideal artwork, to choosing premium materials and applying advanced printing techniques, every step ensures a product that is both visually stunning and durable.

Premium playing cards are perfect for corporate promotions, personalized gifts, and collectible items. They offer both functionality and aesthetic appeal, making them an excellent choice for any occasion. Whether you're aiming to create a unique promotional tool or a memorable gift, the quality of your playing cards will leave a lasting impression.

For top-tier custom playing card manufacturing, Yahong Printing Technology Co., Ltd. is your trusted partner. Specializing in high-quality printing and material selection, they can help bring your vision to life. Visit Yahong’s website for more information, and contact their team today to start creating your perfect custom playing cards!